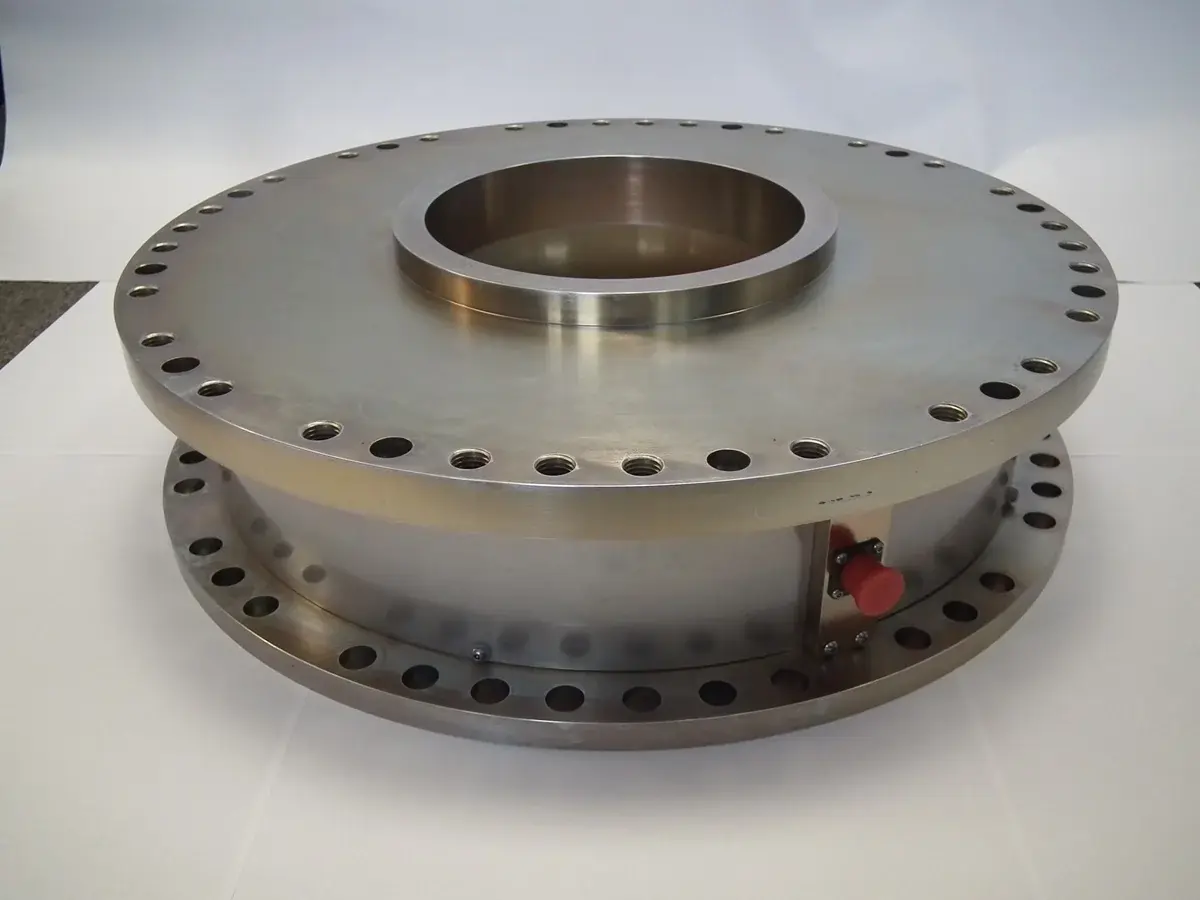

Our largest capacity torque transducers, the AWS Annular Torque Transducers function as a reaction torque transducer to accurately measure torque values. They're used in a variety of industries, and are a favoured solutions in the Oil & Gas and Petrochemical sectors. The annular torque transducer range of 0.2kNm and 300kNm, when used as a reaction transducer, replaces the need for a rotary torque transducer.

Overload Capability

Range covered

Accuracy of the reading from 10 to 100% of rated output

Modes of operation (I Series)

Annular torque transducers comprise of strain gauged torsional tubes with drive flanges. They are primarily used to measure reaction torque on motor drive systems. This by holding the motor drive system from rotation measuring reaction torque instead of the complexities of measuring rotary shaft drive torque. This method removes the need for more complex rotary torque measuring transducers, also the additional inertia component if using a rotary transducer.

They can also be used as an inline torque transducer with appropriate drive shafts and flanges.

The series of AWS Annular Torque Transducers cover your high torque transducer requirements, covering a range from 0.2 - 300kNm.

AWS Torque Transducers convert mechanical strain into a differential voltage signal. These voltage signals are then interpreted by a display to show your torque reading. It's a well tried and much proven technology, meaning it's less prone to failure than other methods, has high accuracy with long term stability. It also features infinite resolution, and is very temperature stable.

AWS Annular Torque Transducers can be supplied with different output connections, allowing you to use them with the AWS Professional Transducer Display, other manufacturer's analogue displays or other manufacturer's displays which work with smart chip transducers. More details on this are listed below.

Being an independent company, our equipment can be easily calibrated by any accredited calibration laboratory wherever they are in the world, allowing you to save time and cost by using local calibration services with short lead times.

AWS can custom design and manufacture Annular Transducer Mounting Adapters to suit your mounting requirements, allowing you to fit annular torque transducers into your current setups whilst maintaining the accuracy of your torque application results.

Manufactured to a high tolerance out of hardened stainless steel which helps eliminate corrosion and increase the lifetime of the torque adapter. Laser engraving on the adapter makes it easy to identify the size and model number.

The AWS Annular Torque Transducers can be supplied to work with a variety of displays to suit your requirements. Each series outlined below is designed to have different features, and to be compatible with one type of torque display.

When used with the AWS Professional Transducer Display, the I Series range of torque transducers can be used in three modes of operation.

Used for click type torque tools, 1st Peak Mode detects, shows and retains the first peak reading in a fast dynamic memory, or is cleared automatically after three seconds if the auto cancel option is selected.

Used for dial and cam type torque tools, Peak Mode shows, updates and retains the maximum reading in a fast dynamic memory. The maximum reading is retained until manually cleared.

Run Mode shows the torque value as they change as a live reading output.

| I Series Model Number | 1038 | 1039 | 1031 | 1032 | 1033 | 1034 | 1035 | 1046 | 1036 | 1037 |

| A Series Model Number | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 | 2035 | 2046 | 2036 | 2037 |

| N Series Model Number | 3038 | 3030 | 3031 | 3032 | 3033 | 3034 | 3035 | 3046 | 3036 | 3037 |

| Range | 0.2 - 2kNm | 0.3 - 3kNm | 0.5 - 5kNm | 1 - 10kNm | 2 - 20kNm | 5 - 50kNm | 10 - 100kNm | 12 - 120kNm | 20 - 200kNm | 30 - 300kNm |

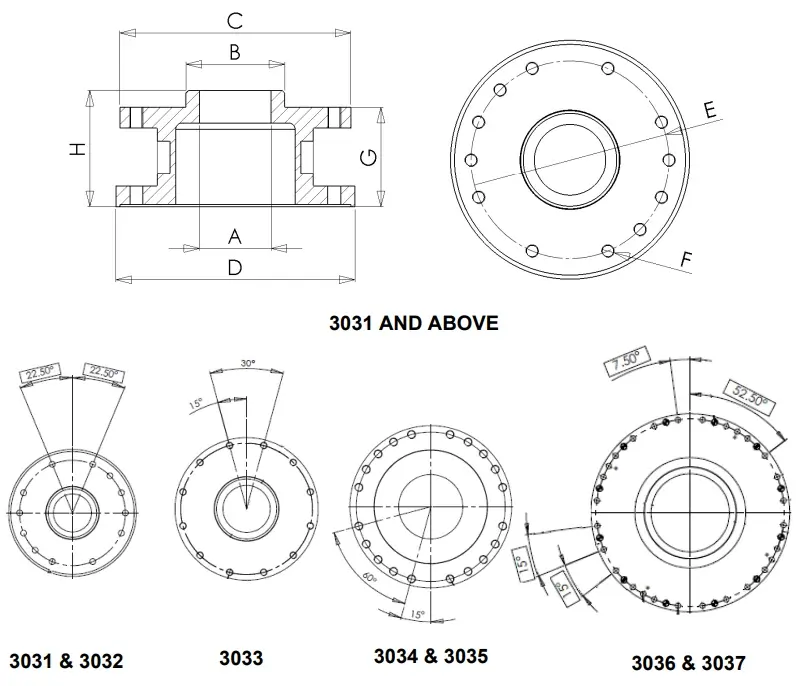

More Than 3kNm Dimensions (All dimensions in mm unless specified otherwise)

| Capacity | A | B | C | D | E | F | G | H | Number of Bolts | Bolting Torque | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5kNm | 55 | 76 | 177.8 | 184 | 152.4 | M10 x 1.5 | 77 | 90 | 24 | 58Nm | 6.1 |

| 10kNm | 55 | 76 | 177.8 | 184 | 152.4 | M10 x 1.5 | 77 | 90 | 24 | 58Nm | 6.3 |

| 20kNm | 70 | 95 | 212 | 212 | 195 | M10 x 1.5 | 97 | 76 | 24 | 58Nm | 8.1 |

| 50kNm | 125 | 219.92 | 315 | 315 | 290 | M16 x 2.0 | 126 | 110 | 40 | 248Nm | 24.7 |

| 100kNm | 125 | 219.92 | 315 | 315 | 290 | M16 x 2.0 | 126 | 110 | 40 | 248Nm | 25.3 |

| 120kNm | 125 | 219.92 | 315 | 315 | 290 | M16 x 2.0 | 126 | 110 | 40 | 248Nm | 25.8 |

| 200kNm | 205 | 239.92 | 520 | 520 | 492 | M16 x 2.0 | 130 | 146 | 56 | 248Nm | 52.5 |

| 300kNm | 205 | 239.92 | 520 | 520 | 492 | M16 x 2.0 | 130 | 146 | 56 | 248Nm | 52.5 |

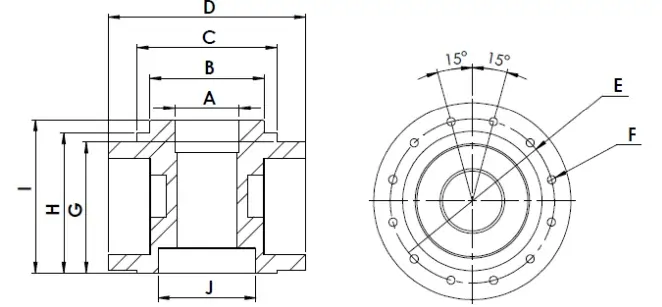

3kNm Or Less Dimensions (All dimensions in mm unless specified otherwise)

| Capacity | A | B | C | D | E | F | G | H | I | J | Number of Bolts | Bolting Torque | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2kNm | 39 | 69 | 84.1 | 119 | 99.06 | M5 x 0.8 | 79 | 84.5 | 92.5 | 59 | 24 | 12Nm | 2.4 |

| 3kNm | 39 | 69 | 84.1 | 119 | 99.06 | M5 x 0.8 | 79 | 84.5 | 92.5 | 59 | 24 | 12Nm | 2.4 |