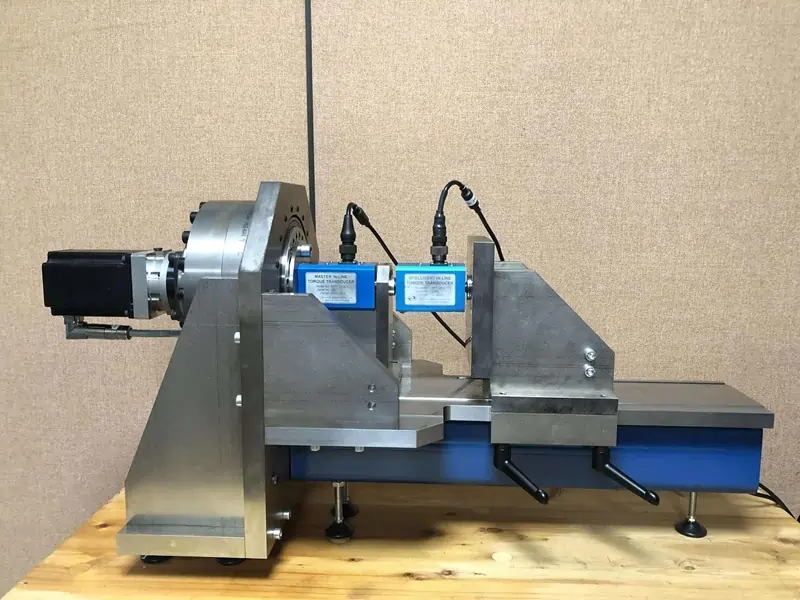

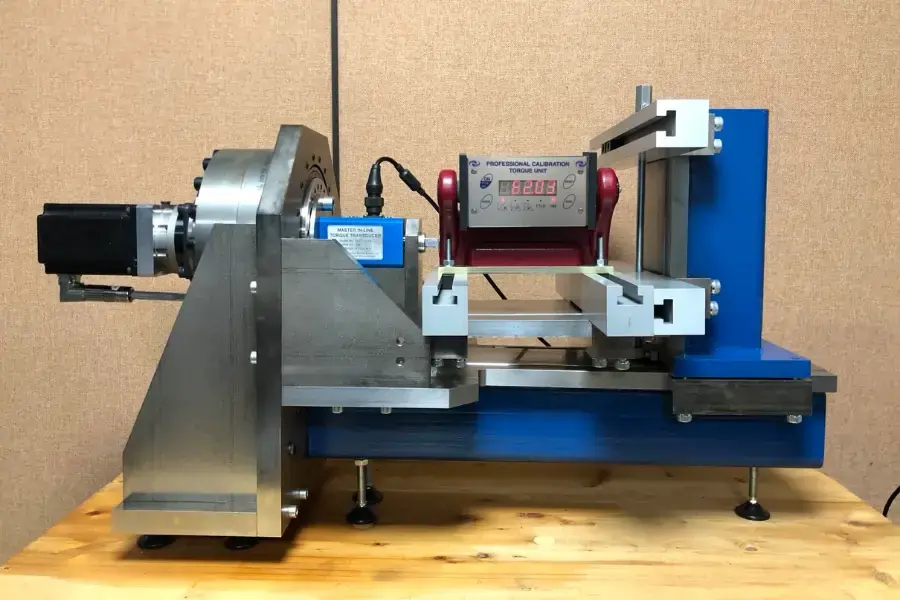

The AWS Universal Torque Calibration Machine is a torque transfer standard, designed to provide a compact, efficient and automated way to calibrate torque measuring devices to BS EN 7882:2017, BS EN 7996:2018 or international standards, replacing the need for beams and weights.

® 6169128

The Universal Torque Calibration Machine uses a high ratio anti backlash gearbox and stepper motor drive to apply and hold up to 2kNm of torque. This is controlled by a lightweight, handheld pendant controller, which features a jog joystick to precisely apply small increments of torque.

You can read more about the benefits of automated operation for your torque calibration setup here.

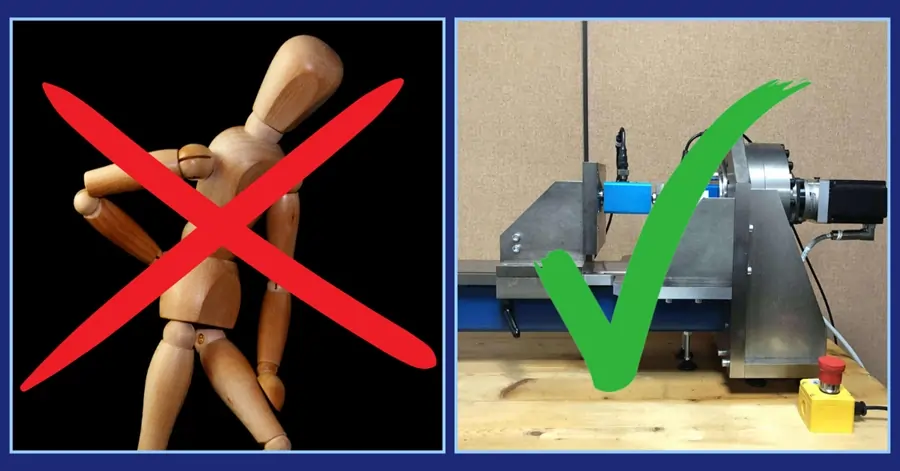

Do you suffer from sore arms and back ache after a hard day lifting weights for your torque measuring device calibrations? That's not a problem with the Universal Torque Calibration Machine!

The machine, being controlled by a handheld pendant controller, eliminates the need for operators to apply weights. Once setup, the calibration readings can even be completed without getting out of your chair!

The Universal Torque Calibration Machine is designed to provide an automated, compact and efficient means of calibrating torque measuring devices to BS EN 7882:2017, BS EN 7996:2018 or international standards.

The automated operation of the Universal Torque Calibration Machine reduces calibration times, and is significantly faster than using the beams and weights method.

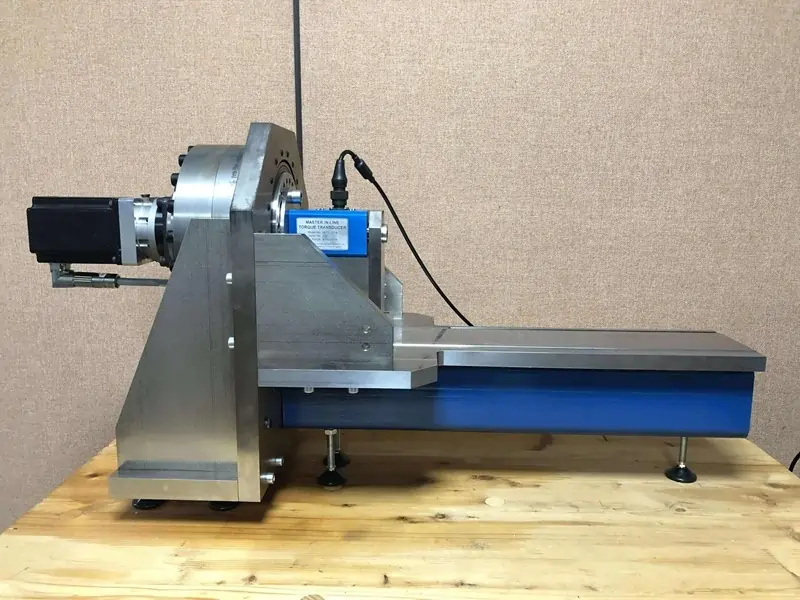

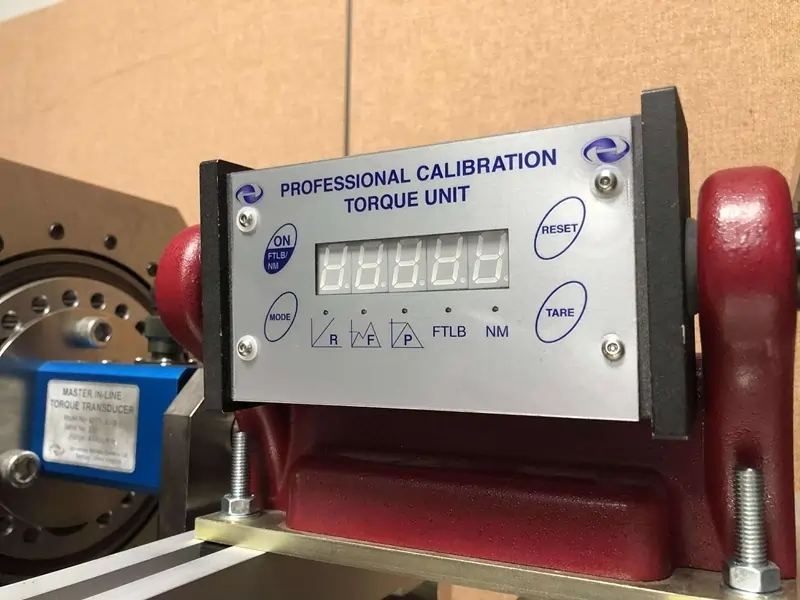

The UTCM uses three AWS Master Torque Transducers (100Nm, 500Nm and 2000Nm) with very high accuracy and stability as well as low uncertainty. The master torque transducers output to an extremely accurate computing 7.5 digit digital voltmeter to display the applied torque to attain a low uncertainty of measurement. A certificate of conformity is provided.

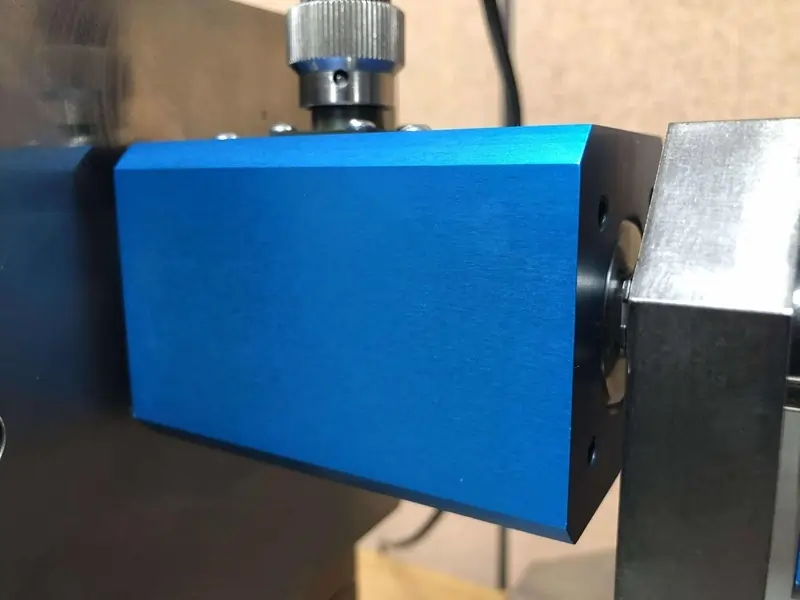

The machine uses AWS Precision Torque Adapters, each designed to accurately fit the model of torque testing device, minimising the uncertainty of torque adapter alignment. Each adapter is made of hardened stainless steel to increase lifespan, and comes laser engraved for easy identification.

Easily interchangeable inline master torque transducers allow for high accuracy and low uncertainty readings of the nominal torque.

The standard range includes three master torque transducers, 100Nm, 500Nm and 2000Nm. This range allows the machine to cover from as low as 4Nm to as high as 2kNm.

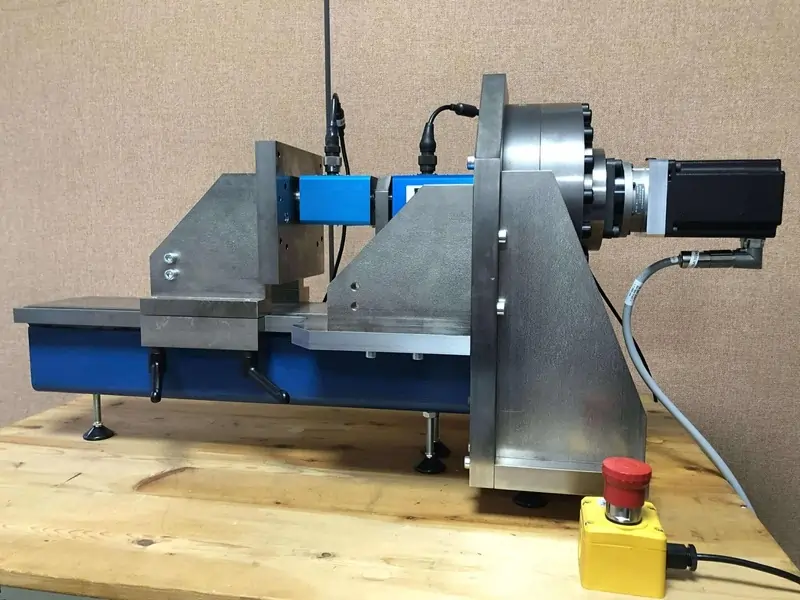

The standard Universal Torque Calibration Machine is designed for the calibration of torque transducers with square drive sizes from 1/4" to 1", and within the range of master torque transducers. A number of optional mounting fixtures are available to suit many devices.

See Optional Extras section below.The Universal Torque Calibration Machine can be operated in both the clockwise and counter clockwise directions.

The Universal Torque Calibration Machine is a bench mounted machine, saving space in your laboratory.

Overload protection ensures that the master torque transducers do not get overloaded during operation.

The emergency stop button can be freely positioned, allowing you to place it in arms reach for easy access. Pressing the external emergency stop button will immediately stop the Universal Torque Calibration Machine from operating.

The Torque Tester Extension is an additional fitting which allows for the calibration of vertical and horizontal mounting torque testers.

The Vertical Mounting Extension further increases the range of torque measuring devices that can be calibrated on the Universal Torque Calibration Machine. This option accommodates the calibration of large vertical or wall mounted torque measuring devices.

Please note, the Vertical Mounting Extension can only be purchased along with the Torque Tester Extension.

Increase the range of square to square drive sizes the Universal Torque Calibration Machine can accommodate by using AWS Precision Torque Adapters.

The AWS range of Precision Torque Adapters are precision machined to high tolerances to ensure maximum accuracy and minimal uncertainties in your torque application.

- Electronic drive system and push button pendant controller, eliminating the need for the operator to manually apply torque.

- Sliding carriage for the calibration of standard sized torque transducers up to a 1" (25.4mm) square drive. This drive size can be decreased with the use of AWS Precision Torque Adapters.

- Optional additional sliding carriage and fittings for the calibration of a wide variety of torque measuring and calibration devices. Multi-axis T slot system supports a range of fixing positions.

- The torque applied by the UTCM is indicated by a computing nano-voltmeter, converting mV from the transducer to units of torque. A stable voltage source energises the transducers.

Technical Specification

| Rated Torque | 4Nm to 2kNm |

| Dimensions | 94cm Length by 34cm Width by 40cm Height |

| Weight (Main Body - Without Torque Transducers and Carriages) | 90kg |

| Weight (Transducer Sliding Carriage) | 16.7kg |

| Weight (Torque Tester Sliding Carriage - Depending on Options) | 24 - 40.5kg |

| Weight (2kNm Transducer Cassette) | 13.5kg |