The AWS Universal Torque Wrench Calibration Machine provides an efficient and automated means of calibrating and testing manually operated torque wrenches to ISO 6789:2017 or company specific standards and specifications.

® 6169133 | ® 6169134

The microcontroller ensures the torque wrench calibrator adheres to the minimum target torque approach times for the capacity of the torque tool being calibrated, as required by the ISO 6789:2017 international standard for manual torque tools.

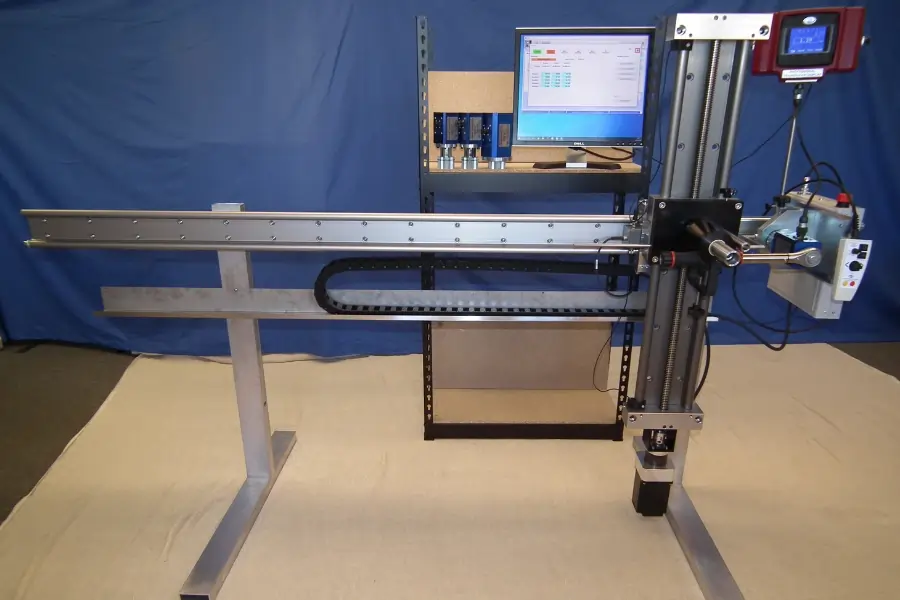

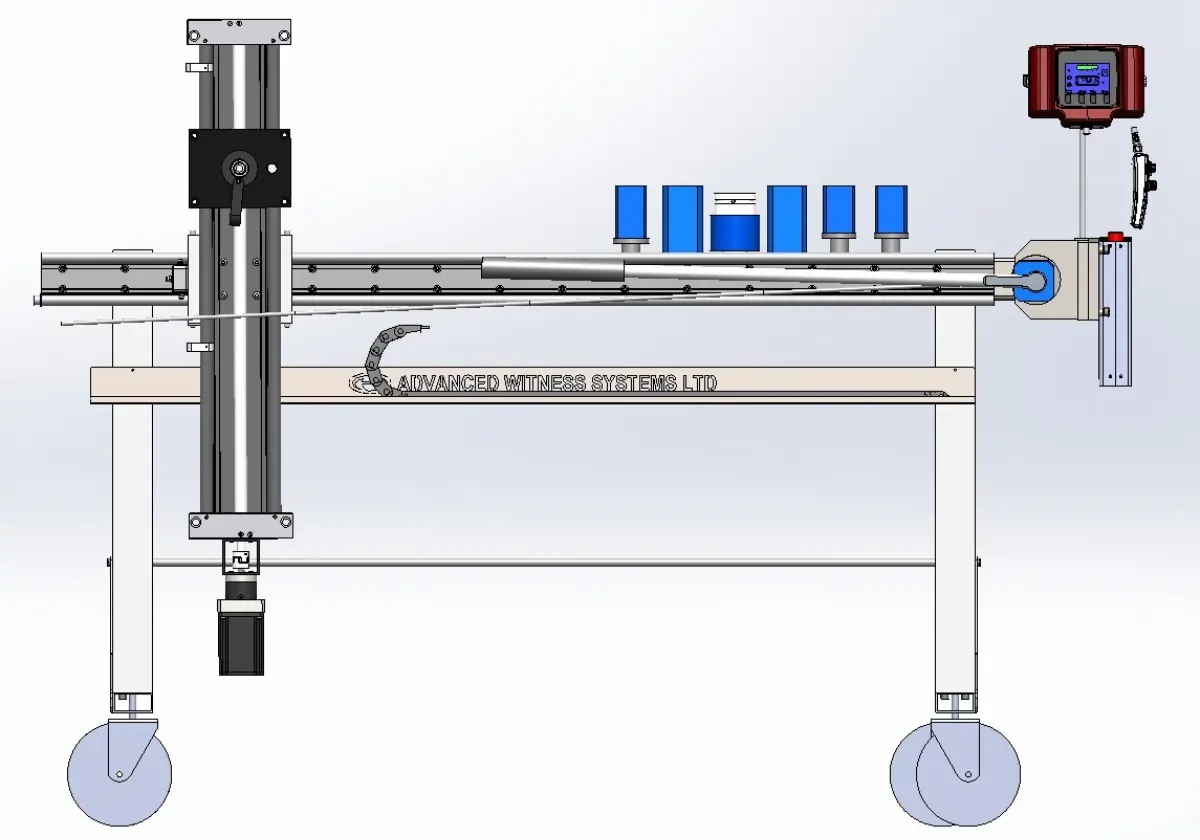

The Universal Torque Wrench Calibration Machine is available in 500Nm, 1500Nm and 3000Nm ranges. Each range can be supplied with automated operation or semi - automated operation to meet your requirements.

The 500Nm version of the Universal Torque Wrench Calibration Machine is desktop / bench mounted for space saving, whilst the 1500Nm and 3000Nm versions are free standing.

The torque display is height adjustable to allow it to fit in with your surroundings.

The torque wrench calibrator runs via automated operation at the press of a button on the handheld pendant controller, removing the need for operators to apply high application forces to the handle of torque wrenches.

The automated versions of the Universal Torque Wrench Calibration Machine detect a first peak signal for setting type wrenches, stopping the tool and returning to zero automatically.

The dial on the handheld pendant controller and the inbuilt microcontroller allows the user to have accurate control of force applied and operation speeds to maintain compliance with ISO 6789:2017.

You can read more about the benefits of automated operation for your torque calibration setup here.

Due to the automated operation of the torque wrench calibrator, typical torque wrench calibration time to ISO 6789:2017 is only 60 minutes, 33% faster than manual methods.

Due to the potential for faster throughput of torque wrenches through your laboratory, Return on Investment can be as short as just 9 months!*

* Based on approximate cost of UTWCM, 6 calibrations per day, £35/hour hourly rate

Our independence from torque wrench manufacturers and detailed knowledge of the marketplace, has enabled us to develop this truly Universal Torque Wrench Calibration Machine, able to calibrate any hand torque wrench regardless of manufacturer, type or class.

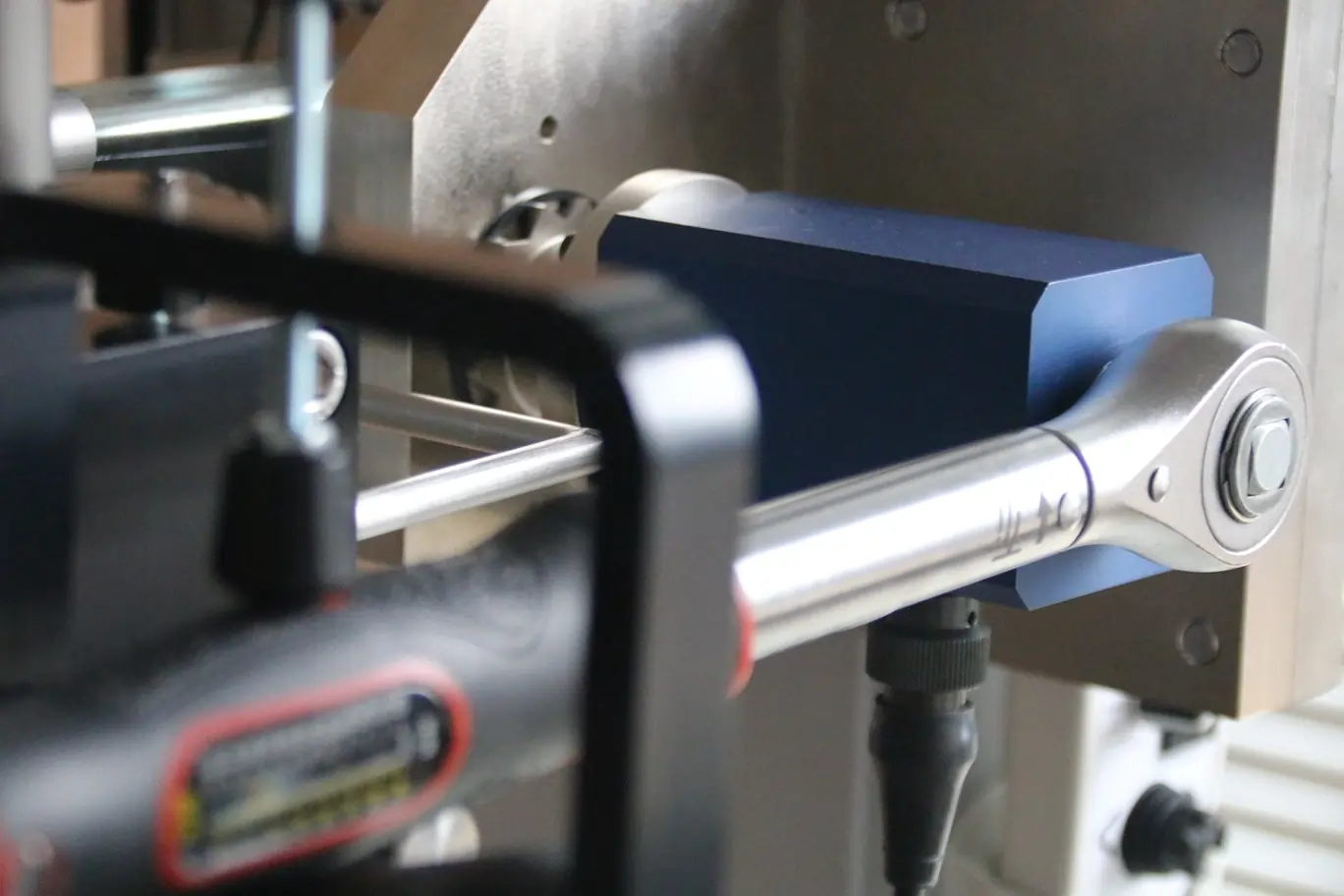

The torque wrench calibrator is able to calibrate manually operated Click, Cam and Indicating type torque wrenches.

The long cross bed travel on the calibrator allows for easy tool alignment and for cam type torque wrenches to be calibrated on the machine.

To accommodate torque wrenches with fixed heads, the torque transducer mounts in our carriages can be rotated 360° in steps of 30°.n steps of 30°.

The Universal Torque Wrench Calibration Machine places special emphasis on the minimisation of parasitic forces applied to the handle of the torque wrench during a tool's calibration, increasing the accuracy of your results.

During operation, the handle of the torque wrench is held in a position such as it would be in general use in the field.

The Universal Torque Wrench Calibration Machine is designed to simplify the process of completing torque wrench calibrations to ISO 6789:2017, making it far easier to fill the gaps left by staff annual leave or sickness and continue the fast throughput of torque wrenches through your laboratory.

The torque wrench calibrator works with the Professional Transducer Display to run automatically at the press of a button for setting type wrenches, reducing necessary operator input, effort and skill.

A manual and prompt cards are provided with the calibrator to aid technicians.

AWS staff can guide you through the setup process, as well as first time use to ensure you can get up and running quickly.

The highly accurate AWS Intelligent In-Line Torque Transducers are used with the Universal Torque Wrench Calibration Machine. They have inbuilt instrumentation to eliminate signal loss, and come in optimised torque ranges to remove the need to change transducers mid torque wrench calibration.

The AWS Intelligent In-Line Torque Transducers can be interchanged between the AWS Universal Torque Wrench Calibration Machine and Universal Torque Screwdriver Calibration Machine, meaning you don't need to buy two torque transducers of the same range when creating your torque tool calibration facility.

Alternatively, the AWS Intelligent Instrumented Transducer Cable allows you to convert your current mV/V transducers from any manufacturer into truly intelligent digital transducers to be used with the torque wrench calibrator.

The Universal Torque Wrench Calibration Machine can be operated in both the clockwise and counter clockwise directions, allowing for dual direction calibrations of a variety of torque wrenches on the machine.

The ISO 6789:2017 compliant Universal Torque Wrench Calibration Machine peaks at just 55dB during calibration and needs little maintenance to run reliably so you can keep your technicians focussed on performing calibrations.

The Upper Limit stops the calibrator if 110% of the transducer maximum load is detected. This torque setting can also be manually set to lower values.

Pressing the red button on the handheld will stop the calibration machine from operating.

Easily accessible emergency stop button to stop the calibration machine at any stage of the operation.

Travel limit sensors will stop the calibration machine from travel over-running.

The 1500Nm and 3000Nm versions of the Universal Torque Wrench Calibration Machine can be fitted with the UTWCM Mobility Kit for easier manoeuvrability of the calibrator. The kit modifies the machine's legs with four 50mm lockable castor wheel, each able to swivel 360 degrees.

All ranges of the Universal Torque Wrench Calibration Machine are available in Automated and Semi Automated Versions.

Technical Specification

| Rated Torque | 500Nm, 1500Nm or 3000Nm |

| Dimensions 500Nm Version | 110cm Width by 90cm Height. Requires desk space of 70cm wide and 75cm deep. It overhangs the front of the desk by 45cm, and requires 56cm of space above the table. |

| Dimensions 1500Nm Version | 77cm Length by 205cm Width by 135cm Height. |

| Dimensions 3000Nm Version | 77cm Length by 266cm Width by 135cm Height. |

| Operating Voltage | 110 / 230 V AC 50~60 HZ |

| Spline Drives for Mounting Torque Transducers | 1/4", 3/8", 1/2", 3/4", 1", 1.5" Female Square Drive |

| Max Wrench Length 500Nm Version | 850mm |

| Max Wrench Length 1500Nm Version | 1800mm |

| Max Wrench Length 3000Nm Version | 2400mm |

| Cross Bed Travel for 500Nm Version | 360mm |

| Cross Bed Travel form 1500Nm & 3000Nm Versions | 700mm |