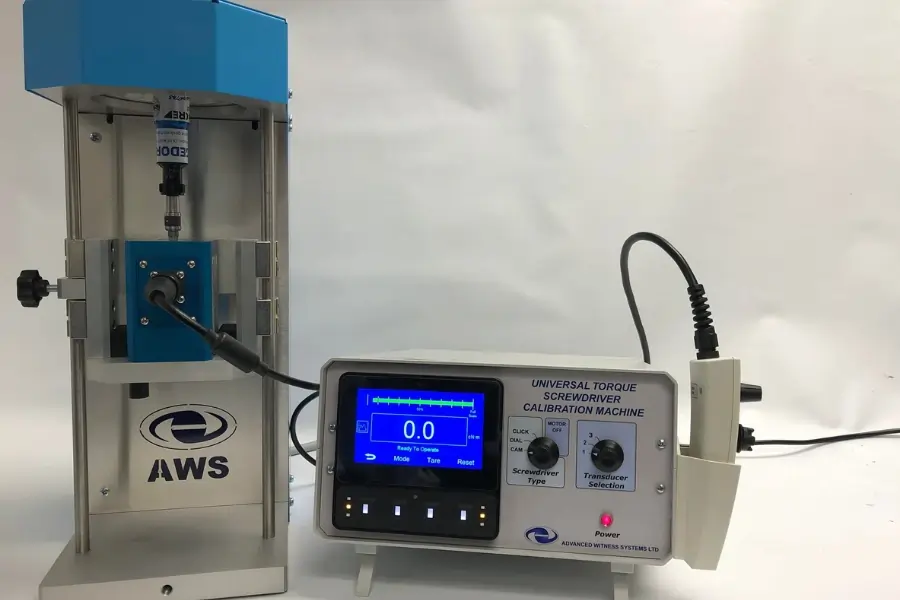

The AWS Universal Torque Screwdriver Calibration Machine for compliance to ISO 6790:2017 provides an efficient and automated means of calibrating and testing manually operated torque screwdrivers to international or company specific standards and specifications.

® 6169127 | ® 6169130

The desktop AWS Universal Torque Screwdriver Calibration Machine is the only known torque screwdriver calibrator on the market that meets ISO 6789:2017 standards on the market today! * It's currently being used in a number of accredited calibration laboratories around the world.

The automated operation of the calibrator means calibration times are up to 10 times faster than manual methods.

The Universal Torque Screwdriver Calibration Machine performs a learning cycle before each calibration to learn and store the timings required for each individual cam position to meet the timing requirements of the ISO 6789:2017 standard.

* As of time of publishing (15/08/2025).

The torque screwdriver calibrator provides an efficient means of calibrating and testing manually operated torque screwdrivers to international or company specific standards and specifications, including ISO 6789:2017, up to 30Nm.

The calibration machine is able to cover a range from 0.05Nm to 30Nm dependant on the range of AWS Inline Torque Transducers purchased.

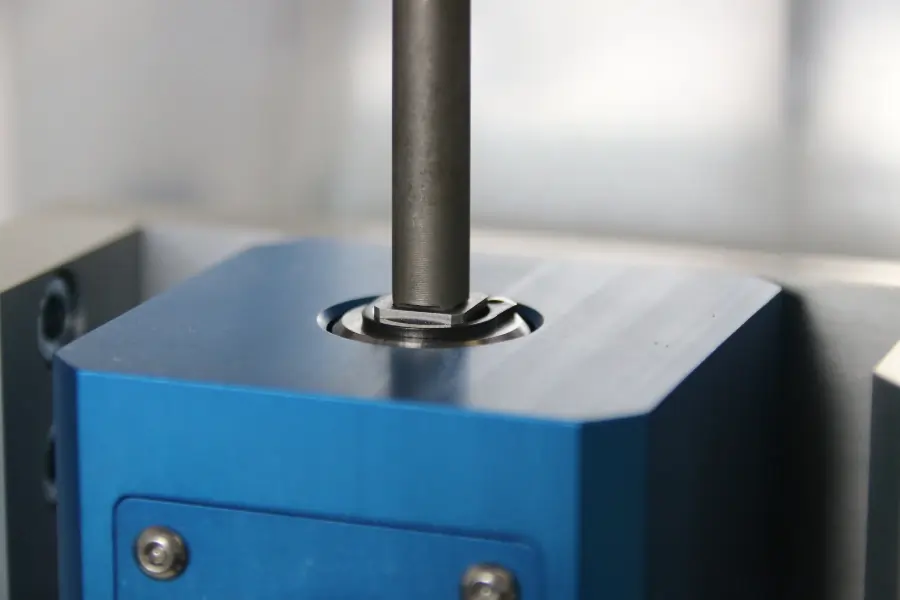

The Universal Torque Screwdriver Calibration Machine automatically detects the first peak signal for click and cam type screwdrivers, stops the torque screwdriver calibrator and then returns or runs on to zero, resetting the screwdriver.

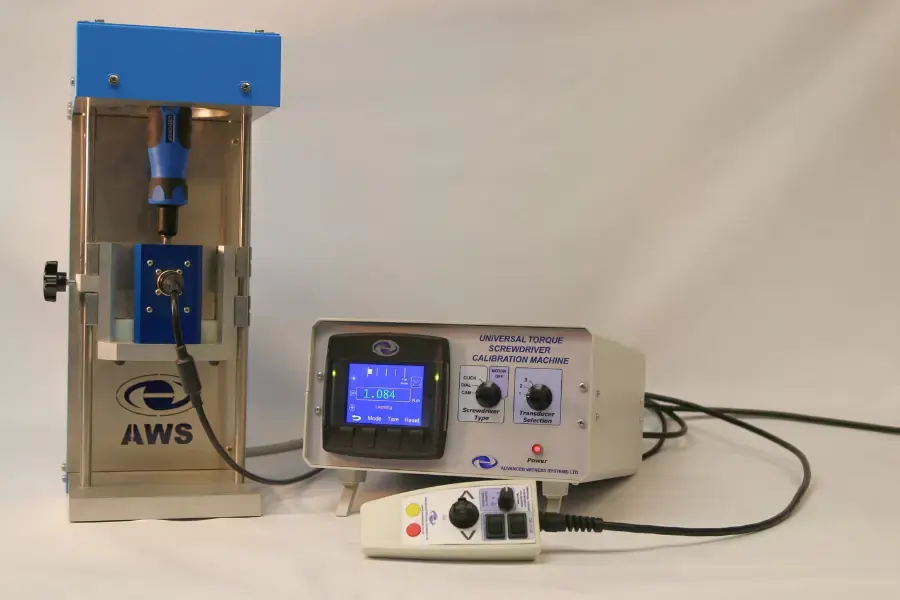

The torque screwdriver calibration tool is operated via a handheld pendant controller meaning torque is applied at the press of a button.

The user can select the number of consecutive operations that are performed by using a dial on the handheld controller to choose between 1, 3, 5 or 10 operations.

The Universal Torque Screwdriver Calibration Machine operates very quietly, with typical operation volume around 30db.

You can read more about the benefits of automated operation for your torque calibration setup here.

Using the AWS Universal Torque Screwdriver Calibration Machine, typical torque screwdriver calibration times to ISO 6789:2017 standards is just 25 minutes.

Torque Screwdriver Calibration times can be greatly sped up by performing 10 operations consecutively using the dial on the handheld controller.

Due to the potential for faster throughput of torque screwdrivers through your laboratory, Return on Investment can be as short as just 10 days!*

* Based on approximate cost of UTSCM and 3 torque transducers, 12 torque screwdriver calibrations per day, £35/hour hourly rate.

Our independence from torque screwdriver manufacturers and detailed knowledge of the marketplace, has enabled us to develop this truly universal torque screwdriver calibration tool, able to calibrate any hand torque screwdriver up to 30Nm, regardless of manufacturer, type or class.

A dial on the front of the machine's control box allows you to select between Click, Cam and Dial type torque screwdrivers.

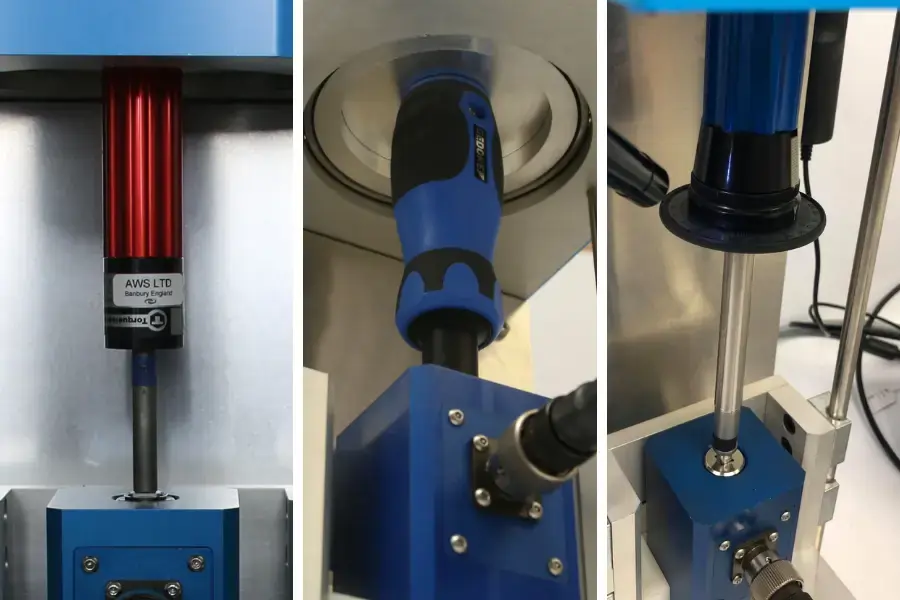

A height adjustable transducer carriage allows you to accommodate the different lengths of torque screwdrivers.

Interchangeable handle adapters allows for the mounting of all known types of torque screwdrivers in the calibrator.

Calibrating torque screwdrivers to ISO 6789:2017 manually is a painstaking and time consuming, which is why we've designed the Universal Torque Screwdriver Calibration Machine to be as simple, automated and easy to operate as possible. This makes it far easier to fill any gap potentially left by staff annual leave or sickness, and maintains the throughput your calibration laboratory.

The torque screwdriver calibrator runs automatically at the press of a button for Click and Cam type torque screwdrivers, greatly reducing necessary operator time, input, effort and skill required.

The calibration machine's manual and prompt cards aid technicians with operation. AWS staff can also assist you through the setup process via online and telephone support.

The Universal Torque Screwdriver Calibration Machine works with AWS Intelligent Inline Torque Transducers to measure the torque applied by the torque screwdriver. These inline torque transducers feature inbuilt instrumentation to remove signal loss due to cable length.

The AWS Intelligent Inline Torque Transducers can be interchanged between the AWS Universal Torque Wrench Calibration Machine and Universal Torque Screwdriver Calibration Machine, meaning you don't need to buy two torque transducers of the same range when creating your torque tool calibration facility.

The torque screwdriver calibrator features an inbuilt 3 Way Transducer Switch Box, to provide thermal stability to up to three transducers at all times. This means that you can quickly select which torque transducer you are using, removing the time required for torque transducer thermal stabilisation.

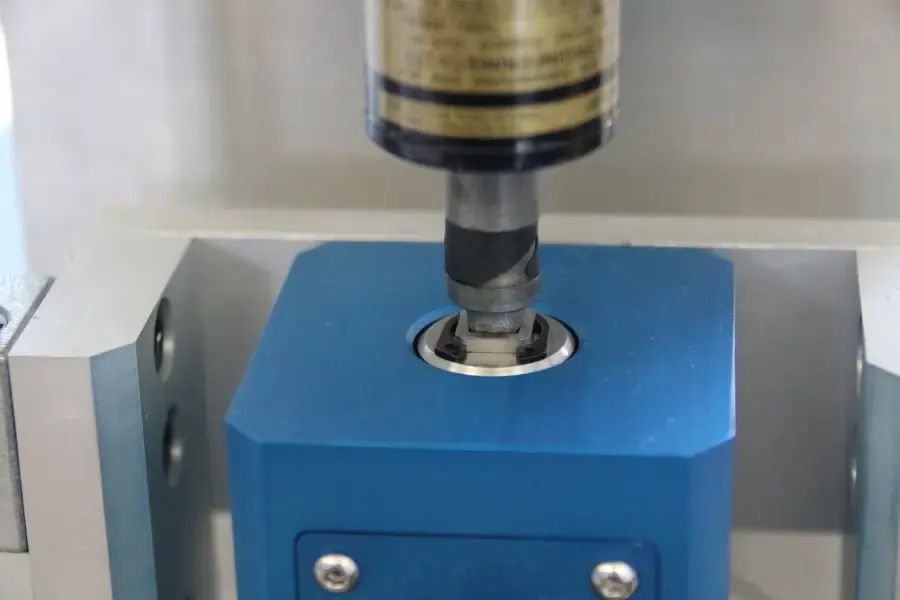

The Universal Torque Screwdriver Calibration Machine grips the torque screwdriver handle using an adapter which is placed in the top of the machine's tower. Torque is applied by the motor rotating this handle adapter.

AWS have two variants of handle adapters for use on the Universal Torque Screwdriver Calibration Machine; solid handle adapters and adjustable handle adapters.

Solid Adapters (shown on the left) are designed to grip one specific model of torque screwdriver, and can be custom designed to fit your most commonly calibrated torque screwdrivers up to 30Nm.

Adjustable Adapters (shown on the right) can be tightened onto the handles of a variety of torque screwdrivers up to 10Nm, allowing multiple handle designs to be calibrated using just one adapter.

Both types of adapters fully comply with the ISO 6789:2017 Part 1 requirement that the torque screwdriver must be held within ±2° of the vertical.

The Universal Torque Screwdriver Calibration Machine operates in both the clockwise and counter clockwise directions, for dual direction calibrations of a variety of torque screwdrivers on the machine.

The Universal Torque Screwdriver Calibration Machine is quiet, with the only discernible noise being the click of the screwdriver itself. Requires minimal maintenance.

Overload detection stops the torque screwdriver calibration tool if 110% of the torque transducer's maximum load is detected. This torque setting can also be manually set to lower values during the setup stage.

Pressing the red button on the Universal Torque Screwdriver Calibration Machine's handheld controller will stop the tool from operating.

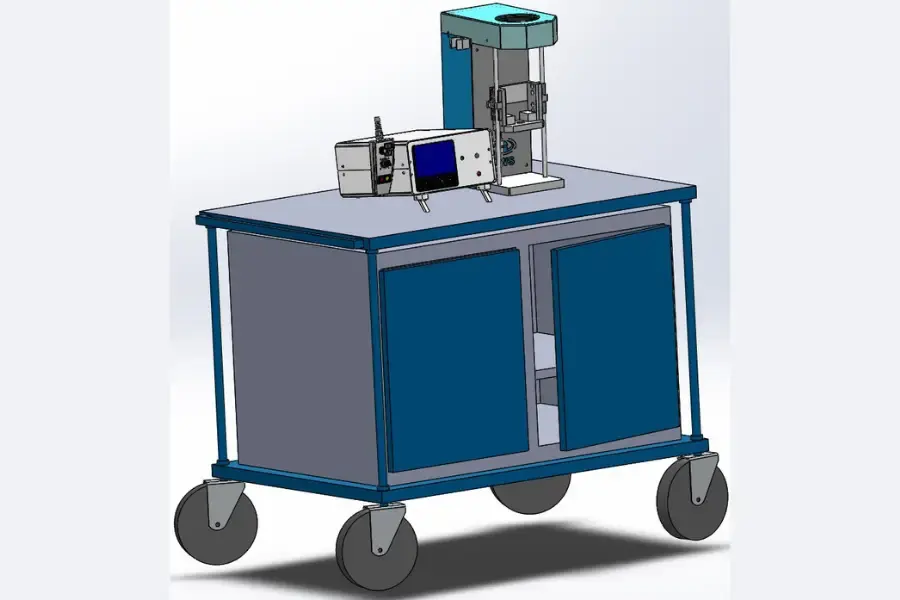

The Universal Torque Screwdriver Calibration Machine can be supplied with the AWS UTSCM Mobility Kit for increased portability of the machine around a facility. The calibrator bolts securely atop a durable, steel sheet workshop trolley, featuring lockable castor wheels with solid rubber treads, and a practical handle for easy movement whilst also ensuring stability during a calibration. Two lockable cabinets with removable shelves within the trolley provides secure storage of tools or equipment to be used during the torque calibration.

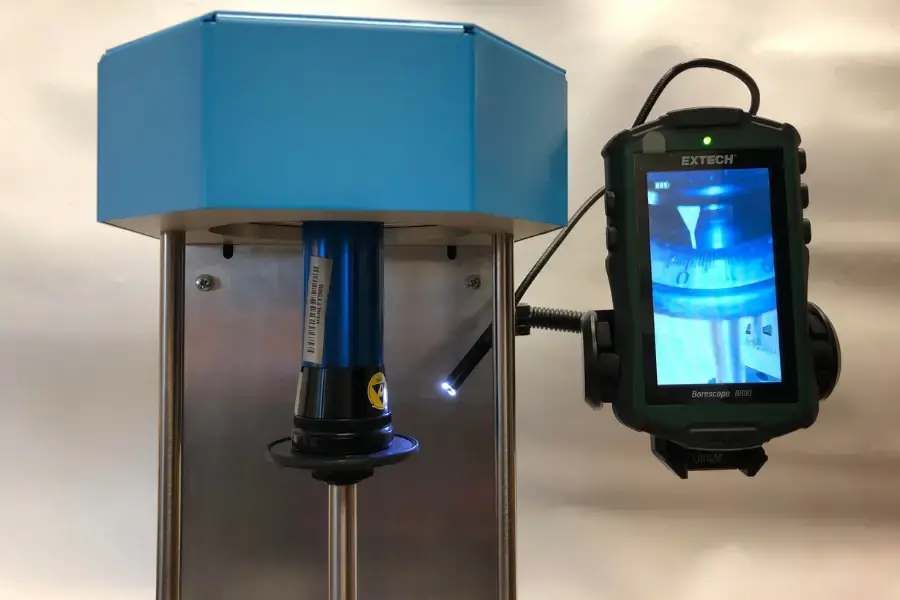

Our standalone camera for the Universal Torque Screwdriver Calibration Machine allows for easier viewing of difficult to read dial type torque screwdrivers on its clear 480 pixel display.

Use of the camera also helps reduce scale parallax error from dial type torque screwdriver calibrations.

- The Universal Torque Screwdriver Calibration Machine applies the torque to the tool via a tooth belt drive driven by a stepper motor and an AWS microcontroller.

- Featuring 5 easily selectable torque units, allowing you to view and record your torque readings in Nm, Lbf.Ft, cNm, Lbf.In and ozf.In.

- The hand controller allows for fast movement and jog facilitate for the quick setup of individual screwdrivers.

- When an AWS Intelligent Inline Torque Transducer is connected, the calibrator automatically programs the display to the correct torque transducer range.

- The AWS Universal Torque Screwdriver Calibration Machine (UTSCM) is fitted with our Timing Module to demonstrate verification of the screwdriver timing requirements to ISO 6789:2017. This provides an independent timing output, allowing verification of the time to apply the last 20% of the target torque. This output is provided via an insulated BNC connector on the rear of the calibrator, and takes the form of a +2.5V signal when the torque reaches 80% of the target torque, which returns to 0V when the Peak is detected. The width of this pulse can be measured to verify the timings meet the stringent screwdriver requirements of the ISO 6789:2017 standard.

Technical Specification

| Rated Torque | 30Nm |

| Dimensions | 31cm Length by 45cm Width by 45cm Height |

| Weight | 16.5kg with an AWS IITT torque transducer, Control Box Weight: 5kg |

| Accuracy | Better than 1% of the reading from 4% to 100% of full scale deflection |

| Operating Voltage | 110 / 230 V AC 50~60 HZ |

| Maximum Screwdriver Handle Diameter | 48mm with standard adapters |

| Minimum Screwdriver Handle Diameter | 12mm with standard adapters |

| Number of Active Digits on Display | 6 |

| Display Size | 70mm x 52mm |

| Display Type | Bright, Full Colour, Sunlight Readable LCD Display |

| User Interface | Mode, Unit and Limit Selection Soft Keys |

| Torque Transducer Interface | 3/8" - 1/4" Female Square Drive |

| Number of Simultaneously Connected Torque Transducers | Up to 3 |

| Maximum Distance Between Torque Transducer and Handle Drive Adapter | 230mm |

| Data Output | RS232 |

Downloads