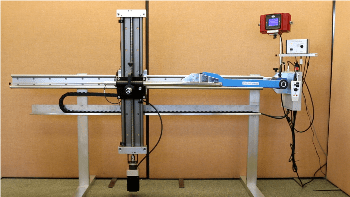

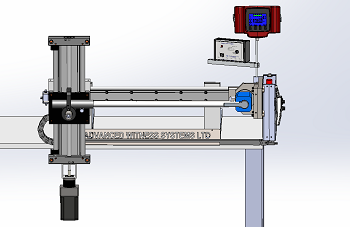

Universal Torque Wrench Calibration Machine

(UTWCM)

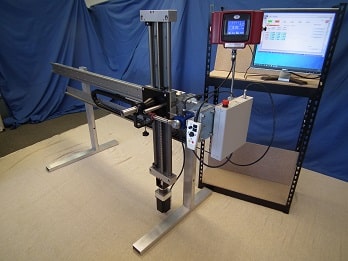

The AWS Universal Torque Wrench Calibration Machine provides an efficient and automated means of calibrating and testing manually operated torque wrenches to ISO 6789:2017 or company specific standards and specifications.

Available in 3 Ranges

The UTWCM is available in 500Nm, 1500Nm and 3000Nm ranges. Each range can be supplied with automated or semi - automated operation to meet your requirements.

Comply to International or In-House Standards

The microcontroller ensures the torque wrench calibrator adheres to the minimum target torque approach times for the capacity of the torque tool being calibrated, as required by the ISO 6789:2017 international standard.

Return on Investment in just 9 Months*

Using the AWS Universal Torque Wrench Calibration Machine, your torque wrench calibrations can be up to 33% quicker than manual methods, meaning payback can be as short as just 9 months with faster throughput of torque tools.*

*Based on approximate cost of the Universal Torque Wrench Calibration Machine, 6 torque wrench calibrations per day, £35/hour hourly rate

Bench Mounted or Free Standing

The 500Nm version of the Universal Torque Wrench Calibration Machine is desktop / bench mounted for space saving, whilst the 1500Nm and 3000Nm versions are free standing. Dimensions of each version can be found in the UTWCM Tech Specs.

Speed Up the Calibration Process

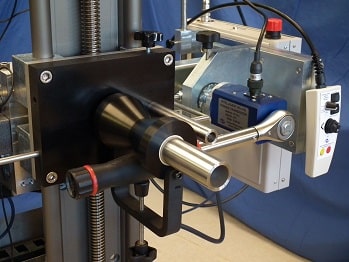

The torque wrench calibrator automatically detects a first peak signal for setting type wrenches, stopping the tool and returning to zero, greatly speeding up the torque tool calibration process.

Independent from Torque Wrench Manufacturers

Our independence from torque wrench manufacturers and detailed knowledge of the marketplace, has enabled us to develop this truly Universal Torque Wrench Calibration Machine.

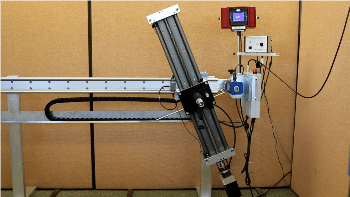

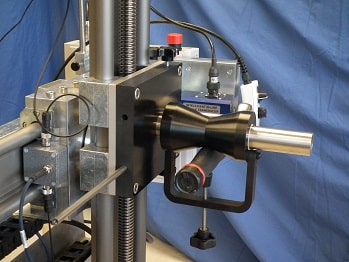

Minimises Parasitic Forces

The torque wrench calibrator places special emphasis on the minimisation of parasitic forces applied to the torque wrench handle during a tool's calibration, increasing the accuracy of your results.

Reduced Operator Input

The torque wrench calibrator works with the Professional Transducer Display to run automatically at the press of a button. The Professional Transducer Display features RS232 output to reduce operator input and eliminate data entry errors whilst using the Universal Torque Wrench Calibration Machine.

Find Out More

® 6169133 | ® 6169134